Piston Rings and failure points

Heavy smoke coming from the breather, poor leak down results, down on power....these are all some of the things that can and will occur if your pistons rings are not treated properly and damage has occurred as a result.

Most of us have heard of a pinched or butted ring. This is probably the most common form of ring / piston failure in a stock engine. Typically you will find this on a OE short block that now has been modified with some sort of boost or nitrous assist. The extra chamber pressure is causing more heat and the rings expand further than what the OE design was so they touch each other. Having no room to move further out due to the cylinder walls, they now start to buckle and force themselves up or down in the land cracking the piston.

When you get into aftermarket builds this can still happen if the rings are not filed to the proper gap. Most engine builders will err on the side of caution if they know it is a boosted engine and open the gap up on the wider side of the tolerance as there is no downside to doing so and will aid in not letting this failure happen.

There is another mode of failure than can still happen with heat and pressure. One of those ways is called collapsed rings. This can happen when to much heat is applied and yet there is still room for the ring to grow on the piston and not touch ends.

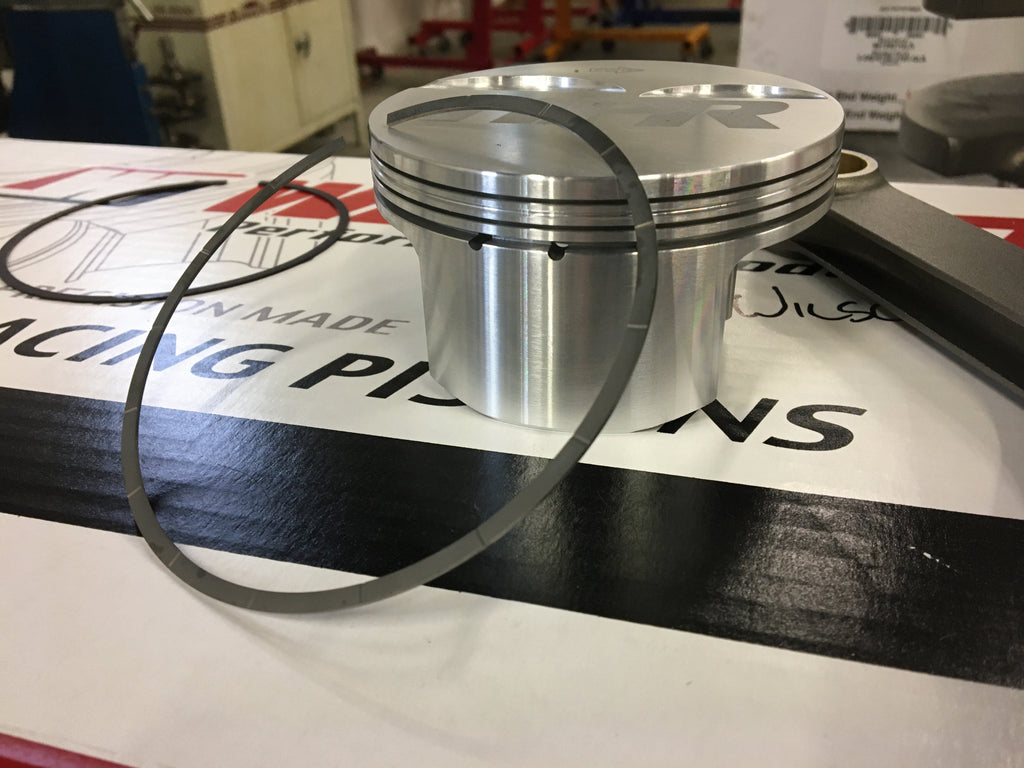

In this picture both rings are actually collapsed but one more so than the other. A good way to check on this during a rebuild is to have your "free gap" measured on the rings when they are still new and compare later during tear down. Some manufacturers can tell you a range to get you close if you do not have new measurements to go off of. On average most of your bigger bore sets are going to be around 0.500" on the top ring and the second ring in the 0.500-0.600" range. This is going to change depending on the static load that ring was designed to work at. If you pull the engine apart and find that you only have 0.200 or 0.300 then something is wrong in the tune or mechanically to cause your rings to have lost their spring tension in the the engine.

Will having a collapsed ring cause the engine to fail? More than likely no it will not because there will still be some ring seal from the combustion gasses in the cylinder it will just not be working as well as it should. Mostt will think that the spring tension is all that is causing your ring to seal and that isn't the case. Primarily it is cylinder pressure that causes the ring to seal which is why you have gas ports in the piston, or in the rings to aid in the sealing process. So sometimes you might not see this collapsed ring that often under WOT but will see far more blow by at idle and low speeds and typically more oil use. Either way it will not be doing it's job and there will be signs.

One other method of failure is micro welding.

This is the transfer of sporadic particles of aluminum from the piston ring groove to the top and bottom of the piston ring in an engine. This happens when the rings get so hot that the aluminum in the ring groove melts and adheres to the bottom of the piston ring causing it to hang up or not move freely in the groove of the piston. Unlike the collapsed ring this typically means the piston is also scrapped or at a min will have to have a wider ring groove cut into it to allow the grooves to go back to the proper smooth surface.

This process can occur early in the break in procedure when the engine is too heavily loaded before the rings have properly seated to the cylinder walls. While it can still happen later on, it isn't as likely once the rings have seated. Later in the engine’s life power adders with high cylinder pressures and extreme temperatures can bring on microwelding as can severe cases of detonation.

So what can you do to prevent these kinds of failures?

Proper ring gap is key #1 and that is included with every piston and ring set, if you have a question contact the manufacture for their input as they are going to know their product better than most.

Careful monitoring of the crankcase pressure during break in is another great way during break in. Apply only light loading to the engine during break in and reduce or eliminate any vacuum being applied to the crankcase during this period. This allows more oil to reach the ring grooves to help facilitate the mating process. If crankcase pressure increases, you can be sure the rings are probably dancing and you better back off and give them more time to seal to the ring groove.

Improving the ring groove and piston ring flatness and surface finish is also a critical factor that piston and ring manufacturers shoot for. Many piston manufacturers will offer a "pro ring groove" which means it is the last machine operation for the piston and thus there is less chance of them being damaged during the machine operations. One other way that has arrived is using a gas ported ring from Total Seal. By doing this, the groove can stay flat with no chance of machine damage from gas ports. When the ring is cut, it is then lapped flat to maintain a better surface finish free of burs.