HPR TT LSx Build Thread Part III

#3 Lifters.

I am choosing to do the lifters before addressing the rods and pistons for a few reasons. In some ways the lifter is often a very over looked part of the equation in a engine build but a vital one. Most people might only think of hydraulic or solid lifters....roller or tappet, but give little thought sometimes to other aspects of the lifter and how that can help a high performance engine survive.

Since all most all domestic engines built since 1986 have had roller lifters I am going to leave out the flat tappet lifters for this discussion.

Hydraulic

Solid

Now what about the lifter itself?

Lifter Diameter:

There are a number of different diameters of lifters that can be used from a stock SBC of 0.842" up to well over 1" in diameter. Of course what you choose to do here is going to depend on what kind of block you have and how much machine work can or is done to it. The larger the body diameter you have the larger wheel you can use as a follower, which we will talk about below. Going to a bigger body lifter typically will allow room more offset pushrod locations, less stress on the lifter body itself, and again more stability in the valvetrain system. With this build, we are using a Jesel DLC coated lifter 0.937" in diameter to gain the room for the bigger wheel shown below.

Jesel link bar, solid roller. 0.937" in diameter

Roller Diameter:

A SBC/LS lifter is going to use a roller diameter of 0.700". This is pretty standard issue and is generally retained on what you would see on a lot of "performance" lifters like LS7's, Comp R, or a drop in Morel or Johnson lifter. One step up from this is going to a 0.750" roller which will help take some stress off of the camshaft itself and can reduce the load placed on both the wheel and the lobe, similar to a big tire in drag racing. By using a larger wheel, you also slow the wheels speed over the cam which reduces friction and heat. This will also allow for a greater redline, given the proper components. Pricing does generally go up when moving into this range. For very aggressive cam profiles this is something that should be looked at very closely and also for those doing extended higher RPM use but do not want to go through the process of using a bigger diameter lifter body. In the case of this build, we are using a 0.850" diameter wheel, again to better stabilize the valve train and reduce stress on the lifters due to the spring rates.

Left to Right: Jesel with a 0.850" wheel, Morel with a 0.750" wheel, stock LS7 with a 0.700" wheel. You can also see the body difference in body size too compared to the stock replacements 0f 0.842"

Lifter travel:

Here there are two kinds of travel. Travel within the lifter itself in the case of a hydraulic but also lifter travel in the bore of the block.

The first is easy enough when dealing with hydraulic lifters. Typically a OE type lifter will have a far greater range to deal with production tolerances and growth of the engine in different climates. A OE lifter might have as much as a quarter of an inch in plunger travel. Some performance lifter applications may see only 0.100 or less making pushrod measurements on a non adjustable valvetrain extremely critical and should be done by someone that has checked before.

Lifter travel within the block itself. Different blocks may use different lifter bore sizes, and different cams with different diameters, base circles will also have different lifter travels as well. All of this is critical so the lifter is correctly placed again for stability but also oiling. Solid or hydraulic the lifter must see pressurized oil for itself and also to supply oil to the rocker arms and valvetrain. In the case of the Jesel lifters we are using they not only have a narrow band for oiling but also small inlets for pressurized oil feeds directly to the axle wheels.

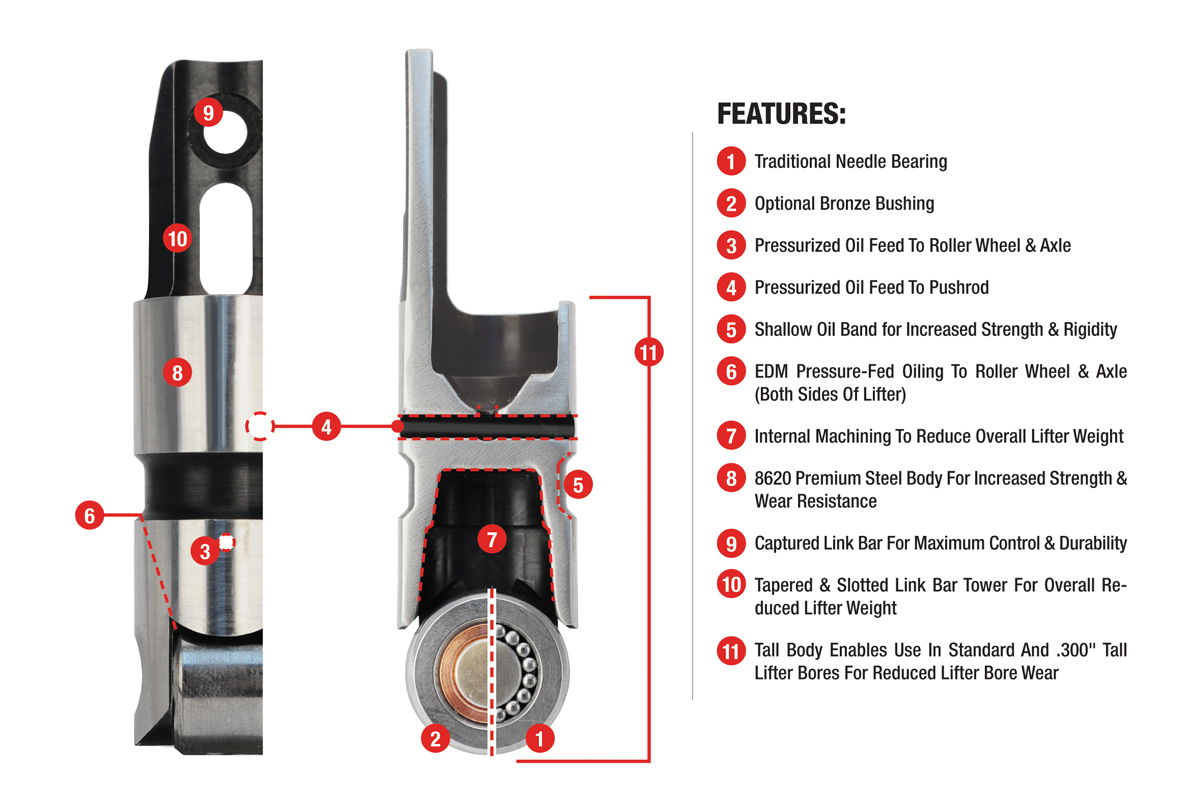

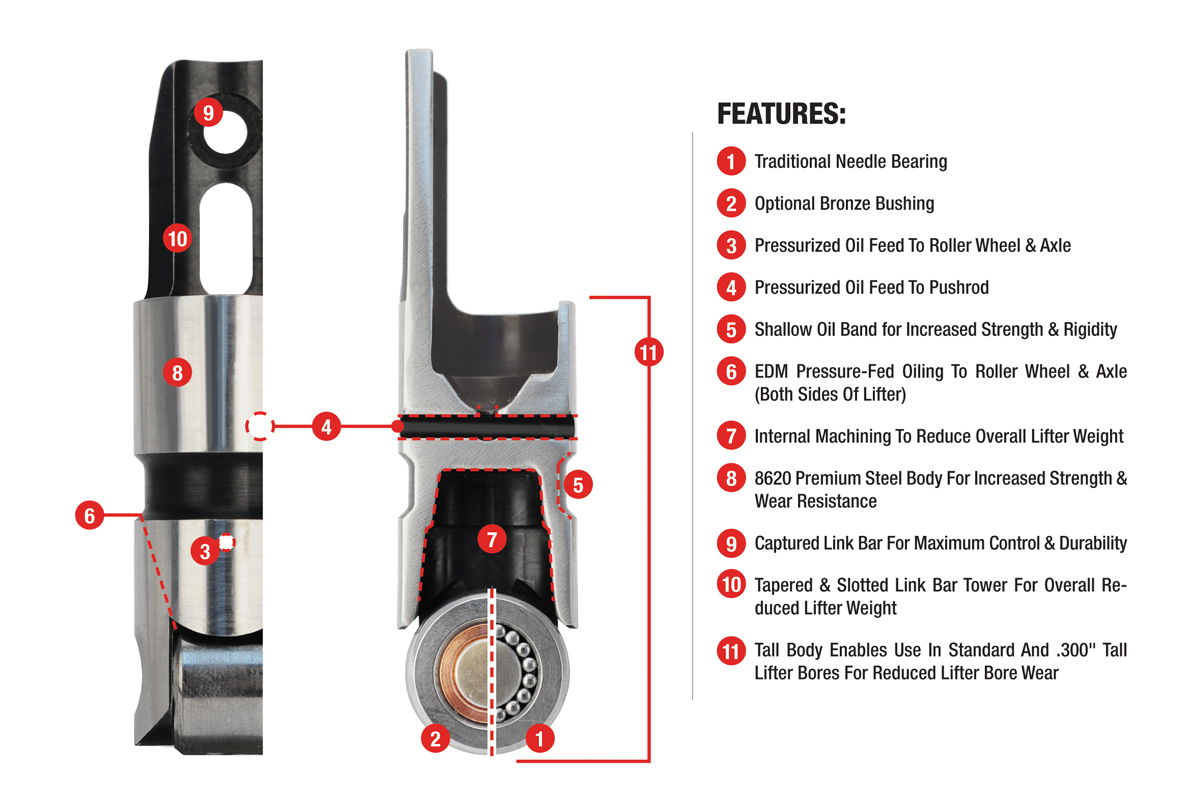

You can see how the oil travels inside the lifter from this Comp Cam's cutaway below. They also mention a taller body for use in different sized lifter bores as well.

Comp Lifter cut away

Special Features:

Every aspect of a build like this must be looked at, and do not think that the pushrods always have to be right in the middle of the lifter because the geometry of a normal V8 might not be correct. In the case of this build, that is what happened. To get the pushrods correctly lined up with the valves and rocker arms above, we had to use a offset lifter only on one side. Companies like Jesel can do these in a variety of ways and offsets depending on what the customer requires.

Jesel offset

Also we chose to do a few other things like using a DLC coated lifter body to drop frictional losses and help lifter wear. The Jesel lifter also contains a roller bearing on the wheel. Some may feel a bushing is better suited here to reduce the number of moving parts or that it might be more reliable. We, and Jesel, feel the frictional loss by using the bearing in this application is the better way to go.

So for a recap on things you need to know to make a correct decision on lifters.

-Solid or Hydraulic

-What diameter am I using or need to use?

-Do I need a larger wheel?

-Do I need to correct any geometry issues?

-Does my block have any special requirements due to oiling?

RACE USE ONLY - NON OE Block

In the event you are building your own billet block, or possibly using a carbon matrix NASCAR block you might find yourself needing a keyway or cartridge style lifter. The keyway lifters, are just how they sound and require a key in the bore to hold the lifter from spinning Generally these are found in diameters of 0.937" up to 1.095" with rollers up to 0.940" These must use aftermarket blocks that are designed and machined to use.

I hope this shows you a little more insight into the little part that could, the lifter.

I am choosing to do the lifters before addressing the rods and pistons for a few reasons. In some ways the lifter is often a very over looked part of the equation in a engine build but a vital one. Most people might only think of hydraulic or solid lifters....roller or tappet, but give little thought sometimes to other aspects of the lifter and how that can help a high performance engine survive.

Since all most all domestic engines built since 1986 have had roller lifters I am going to leave out the flat tappet lifters for this discussion.

Hydraulic

- OEM choice for almost all engines

- "self" adjusting for the most part

- does not require adjustable rocker arms

- easy to use

- quiet operation

- can have issues with big spring pressure and/or high RPM

- mass produced so can be had at a economical price

Solid

- Requires more costly adjustable rocker arms

- nosier operation

- typically requires maintenance for proper adjustment

- great for valvetrain stability and high RPM use

- almost required when running high spring pressures.

Now what about the lifter itself?

Lifter Diameter:

There are a number of different diameters of lifters that can be used from a stock SBC of 0.842" up to well over 1" in diameter. Of course what you choose to do here is going to depend on what kind of block you have and how much machine work can or is done to it. The larger the body diameter you have the larger wheel you can use as a follower, which we will talk about below. Going to a bigger body lifter typically will allow room more offset pushrod locations, less stress on the lifter body itself, and again more stability in the valvetrain system. With this build, we are using a Jesel DLC coated lifter 0.937" in diameter to gain the room for the bigger wheel shown below.

Jesel link bar, solid roller. 0.937" in diameter

Roller Diameter:

A SBC/LS lifter is going to use a roller diameter of 0.700". This is pretty standard issue and is generally retained on what you would see on a lot of "performance" lifters like LS7's, Comp R, or a drop in Morel or Johnson lifter. One step up from this is going to a 0.750" roller which will help take some stress off of the camshaft itself and can reduce the load placed on both the wheel and the lobe, similar to a big tire in drag racing. By using a larger wheel, you also slow the wheels speed over the cam which reduces friction and heat. This will also allow for a greater redline, given the proper components. Pricing does generally go up when moving into this range. For very aggressive cam profiles this is something that should be looked at very closely and also for those doing extended higher RPM use but do not want to go through the process of using a bigger diameter lifter body. In the case of this build, we are using a 0.850" diameter wheel, again to better stabilize the valve train and reduce stress on the lifters due to the spring rates.

Left to Right: Jesel with a 0.850" wheel, Morel with a 0.750" wheel, stock LS7 with a 0.700" wheel. You can also see the body difference in body size too compared to the stock replacements 0f 0.842"

Lifter travel:

Here there are two kinds of travel. Travel within the lifter itself in the case of a hydraulic but also lifter travel in the bore of the block.

The first is easy enough when dealing with hydraulic lifters. Typically a OE type lifter will have a far greater range to deal with production tolerances and growth of the engine in different climates. A OE lifter might have as much as a quarter of an inch in plunger travel. Some performance lifter applications may see only 0.100 or less making pushrod measurements on a non adjustable valvetrain extremely critical and should be done by someone that has checked before.

Lifter travel within the block itself. Different blocks may use different lifter bore sizes, and different cams with different diameters, base circles will also have different lifter travels as well. All of this is critical so the lifter is correctly placed again for stability but also oiling. Solid or hydraulic the lifter must see pressurized oil for itself and also to supply oil to the rocker arms and valvetrain. In the case of the Jesel lifters we are using they not only have a narrow band for oiling but also small inlets for pressurized oil feeds directly to the axle wheels.

You can see how the oil travels inside the lifter from this Comp Cam's cutaway below. They also mention a taller body for use in different sized lifter bores as well.

Comp Lifter cut away

Special Features:

Every aspect of a build like this must be looked at, and do not think that the pushrods always have to be right in the middle of the lifter because the geometry of a normal V8 might not be correct. In the case of this build, that is what happened. To get the pushrods correctly lined up with the valves and rocker arms above, we had to use a offset lifter only on one side. Companies like Jesel can do these in a variety of ways and offsets depending on what the customer requires.

Jesel offset

Also we chose to do a few other things like using a DLC coated lifter body to drop frictional losses and help lifter wear. The Jesel lifter also contains a roller bearing on the wheel. Some may feel a bushing is better suited here to reduce the number of moving parts or that it might be more reliable. We, and Jesel, feel the frictional loss by using the bearing in this application is the better way to go.

So for a recap on things you need to know to make a correct decision on lifters.

-Solid or Hydraulic

-What diameter am I using or need to use?

-Do I need a larger wheel?

-Do I need to correct any geometry issues?

-Does my block have any special requirements due to oiling?

RACE USE ONLY - NON OE Block

In the event you are building your own billet block, or possibly using a carbon matrix NASCAR block you might find yourself needing a keyway or cartridge style lifter. The keyway lifters, are just how they sound and require a key in the bore to hold the lifter from spinning Generally these are found in diameters of 0.937" up to 1.095" with rollers up to 0.940" These must use aftermarket blocks that are designed and machined to use.

Jesel cartridge style key way lifter.

I hope this shows you a little more insight into the little part that could, the lifter.