Rocker arm ratio, spring rates, lash, deflection - WHAT IS MY LIFT!

Thought I would show off some cool pics of engines and do some tech talk along the way today on a customer's Procharged LS Corvette build.

Engine (which I'll do a build on later), is the aluminum full skirt Dart LS block paired with a set of 6 bolt Brodix BR7BS heads that is held down using a 6 bolt setup and 1/2" main head bolts. So not a lot of flex there. Rocker arms are a steel body Crower setup that uses the larger 7/16" offset hold down locations rather than the stock 8mm inline bolt pattern.

So lets get down to the test today. Today we are looking at system deflection and how this is going to relate to spring setup and ultimately actual lift that the engine will see at the valve when everything is assembled for good and running.

Camshaft: Slightly larger than your normal LS cam, this one we are testing with today has a 60mm journal so we could run a bit more lift on the lobe while maintaining a stronger core. This is also the stronger tool steel core as well. Here you can see the rough size difference when placed beside a stock LS cam (don't worry that one won't be used again)

60mm LS Comp cam on the left, OE 55mm core on the right.

Since we are up sizing the camshaft we also chose to upside the lifters as well, all about durability for this one. Jesel DLC coated 0.937 diameter link bar lifters with 0.850 wheels are up from the OE LS 0.842 w/0.700 wheel. This will help keep the lifters more stable in the block, reduce stress on the cam lobes as well as give us some room to offset them to straighten out the pushrods.

Jesel double offset link bar 0.937 lifters

The heads themselves are Brodix BR7-BS heads which offer a nice wide base for the rocker stands, offset mounting bolts for greater stability and much larger 7/16" hold down bolts.

Brodix heads without the stand mounted

Now you may ask, why am I showing this, and why does it matter. The main reason for the background on the above parts is so you can see just how much more robust these are than your normal OE 8mm hold down bolts and stock lifters with a shelf double spring setup. Keep this in mind as the new few measurements are taken. You can also see that each pair of rockers has a rather large shaft going through them and held down to the stand with 3 bolts to lock them in place.

Step one: Stand height setup. Each head / stand pairing is going to have some variation based on the rocker setup, valve length used, and lift of the cam. In this case Crower offers a nice quick rough setup to get you close to what you need to be after bolting the stand in place and torquing it to spec.

Height gauge

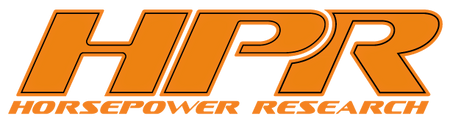

Once your have your stand approx where it needs to be, you can install a pair of checking springs and a pair of your real springs installed to approx where you want to be for install height. Once the head is bolted in place, get your stand setup and align the gauge with the retainer / spring and zero to make sure you can repeat your measurements as you turn the engine over.

One pair of checking springs, one pair of real springs

You will check the valve lift at 0 lash on one intake and one exhaust with the checking spring and then again using this same rocker arm on the intake / exhaust with the real springs installed.

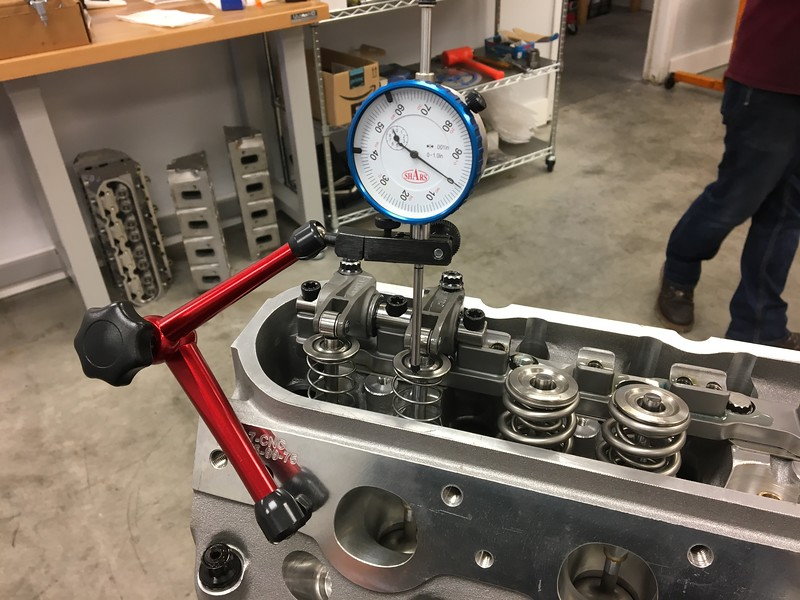

Running through the lift with the real spring

With the engine in question we have 0.440 intake lobe lift, 0.441 exhaust lobe lift. Crower states a 1.8 ratio rocker and the camshaft was ground for a 0.850 wheel lifter.

Final numbers?

Checking springs Intake 0.837" lift at the valve, exhaust 0.835 which gives us a real approx rocker ratio of 1.9 on the intake and 1.89 on the exhaust. I say this because there maybe a slight angle to the pushrods or it might have had a thou or so either way on the lash adjustment and any variance in the gauge itself. Of course this is more than the 0.792 / 0.794 listed on the card due to the slight increase in rocker ratio.

Real spring numbers: We are seeing 220lbs on the seat and approx 740 lbs open pressure with the Comp dual spring setup we have chosen to use. Measurements taken on the pair with the springs installed using the same rocker and same pushrod (7/16 diameter) are 0.807 intake and 0.800 on the exhaust side. So we are loosing approx 0.030 valve lift just due to the assembly bending / moving during opening. This can be in the pushrod, in the rocker arm, in the stand, at the valve...every point is going to have a bit of bending when you are trying to push back on it with over 700lbs of force. Add in about 0.014 lash and your final lift numbers at the valve are now only 0.786 approx.

Is this surprising? No not at all, for that kind of spring pressure getting your deflection under or close to 0.030 is a good number to shoot for. What about the checking spring lift? Again no real surprise here, most rocker companies do fib a little on the rockers and give you a slight bit more than what is stated to make up for things like this. It should be checked because if you are tight on coil bind, or tight P to V then you need to watch this as you might end up with more than you bargained for.

So when customer ask us about solid roller builds, a few things that you see here in this post should be looked at. Do you have to go 60mm cam and big lifter combo? Most certainly not for most solid roller builds that are out there but the stand and how it bolts to the heads is a very important part of this. I'm sure we have all seen someone running a solid roller on a OE head with a big spring and it rip a rocker right out of the head because all it has is one little 8mm bolt holding it down.

Once you have your now "real" data on your setup, you can go back and make sure all of your springs will be setup correctly and free from coil bind.

This is a bit harder to do with a hyd. lifter setup as there is movement to the plunger in the lifter and that will vary with pump up / pump down on the lifters....but hopefully this will show you that things are never 100% what they say on paper when it comes to lift.